Introduction

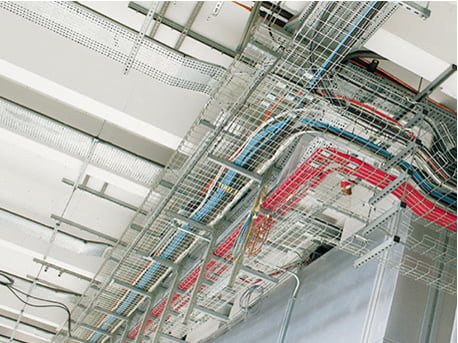

In the intricate landscape of electrical infrastructure, cable trays play a pivotal role in organizing, protecting, and supporting electrical cables. Among the various types available, wire mesh cable trays have emerged as a popular choice due to their distinct advantages and versatility. This comprehensive guide will delve into the intricacies of wire mesh cable trays, exploring their construction, applications, benefits, and considerations for selecting the optimal option for your specific needs.

Note; A “wire mesh cable tray” is known as a “máng cáp dạng lưới” in Vietnamese.

Understanding Wire Mesh Cable Trays

A wire mesh cable tray is a structural component designed to support and route electrical cables. Constructed from a perforated metal sheet, typically galvanized steel or stainless steel, it offers a robust and open-grid structure that provides several key benefits:

- Superior Ventilation: The open mesh design facilitates excellent airflow, preventing heat buildup and ensuring optimal cable performance, especially in environments with high heat generation.

- Easy Installation: Wire mesh cable trays are generally easier to install compared to other types, as they can be cut and shaped on-site to fit specific configurations.

- Flexibility: The open structure allows for easy cable management and modification, accommodating various cable sizes and routing requirements.

- Corrosion Resistance: Galvanized or stainless steel construction provides excellent protection against corrosion, making wire mesh cable trays suitable for both indoor and outdoor applications.

- Aesthetic Appeal: In certain environments, wire mesh cable trays can offer a more aesthetically pleasing appearance compared to enclosed cable trays.

Key Applications of Wire Mesh Cable Trays

Wire mesh cable trays are widely used in a variety of industries and settings, including:

- Data Centers: The open design of wire mesh cable trays helps to dissipate heat generated by high-density server equipment, ensuring optimal performance and reliability.

- Industrial Facilities: In manufacturing plants and factories, wire mesh cable trays provide a safe and organized way to route power cables, control cables, and instrumentation cables.

- Commercial Buildings: Offices, retail spaces, and hotels can benefit from wire mesh cable trays for managing electrical cables in a visually appealing and functional manner.

- Infrastructure Projects: Construction sites, transportation hubs, and utility installations often employ wire mesh cable trays to support and protect cables in outdoor environments.

- Residential Applications: While less common, wire mesh cable trays can be used in high-end residential projects to enhance cable management and aesthetics.

Factors to Consider When Choosing a Wire Mesh Cable Tray

Selecting the right wire mesh cable tray involves careful consideration of several factors:

- Cable Type and Size: The tray must be able to accommodate the specific type and size of cables being routed. Factors such as cable diameter, weight, and heat generation should be taken into account.

- Environmental Conditions: The tray’s material and construction should be suitable for the environmental conditions it will encounter. Factors to consider include temperature extremes, humidity, exposure to corrosive substances, and the potential for outdoor exposure.

- Load Capacity: The tray must be able to safely support the weight of the cables and any additional loads, such as maintenance personnel or equipment.

- Installation Requirements: Consider the ease of installation, accessibility, and compatibility with other components in the electrical system.

- Aesthetics: In certain applications, the appearance of the cable tray may be a factor. Wire mesh cable trays can offer a more visually appealing option compared to enclosed trays, especially in open spaces.

- Code Compliance: Ensure that the chosen cable tray complies with relevant electrical codes and regulations, such as the National Electrical Code (NEC) in the United States.

Material Selection

Wire mesh cable trays are typically made from galvanized steel or stainless steel. Each material has its own advantages:

- Galvanized Steel: Offers a good balance of strength, durability, and corrosion resistance. It is suitable for most indoor and outdoor applications.

- Stainless Steel: Provides superior corrosion resistance and is ideal for environments with high levels of moisture, humidity, or exposure to corrosive substances.

Additional Considerations

- Accessories: Wire mesh cable trays can be complemented with various accessories, such as fittings, elbows, tees, and end caps, to create a complete cable management system.

- Maintenance: Regular inspection and maintenance are essential to ensure the integrity and safety of wire mesh cable trays. This includes checking for damage, corrosion, and loose connections.

- Cost: While wire mesh cable trays may have a slightly higher initial cost compared to some other options, their long-term durability and benefits can justify the investment.

Choosing the Right Cable Tray for Your Needs

The optimal wire mesh cable tray for your specific application will depend on a combination of factors, including:

- Cable Type: The tray must be able to accommodate the specific type and size of cables being routed.

- Environmental Conditions: The tray’s material and construction should be suitable for the environment it will be exposed to.

- Load Capacity: The tray must be able to safely support the weight of the cables and any additional loads.

- Installation Requirements: Consider the ease of installation, accessibility, and compatibility with other components.

- Aesthetics: In certain applications, the appearance of the cable tray may be a factor.

Installation Guidelines

- Planning and Design:

- Determine the cable routing and tray layout based on the specific application and requirements.

- Consider factors such as cable density, heat dissipation, and accessibility.

- Ensure that the tray design complies with relevant electrical codes and regulations.

- Preparation:

- Clear the installation area and ensure a stable surface for mounting the trays.

- Gather necessary tools and equipment, including measuring tape, level, drill, screws, and appropriate fasteners.

- Tray Installation:

- Mount the tray sections to the designated support structure using appropriate fasteners.

- Ensure that the trays are securely attached and level to prevent sagging or misalignment.

- Consider using expansion joints or flexible couplings to accommodate thermal expansion and vibration.

- Cable Routing:

- Carefully route the cables through the tray sections, ensuring proper support and spacing.

- Avoid overcrowding the tray to prevent overheating and potential damage.

- Use cable ties or straps to secure the cables within the tray and prevent movement.

- Grounding:

- Connect the tray to the grounding system to ensure electrical safety.

- Follow relevant electrical codes and standards for grounding requirements.

Maintenance Tips

- Regular Inspections:

- Conduct periodic inspections to check for signs of damage, corrosion, or loose connections.

- Look for any evidence of overheating, cable chafing, or other issues.

- Address any problems promptly to prevent further damage or safety hazards.

- Cleaning:

- Remove any accumulated dirt, dust, or debris from the tray and cables.

- Use a soft brush or compressed air to clean the tray and cables gently.

- Avoid using harsh chemicals or abrasive materials that could damage the tray or cables.

- Tighten Connections:

- Periodically check and tighten any loose fasteners or connections.

- Ensure that the tray is securely mounted and that the cables are properly secured within the tray.

- Cable Management:

- Maintain proper cable management practices to prevent excessive strain or stress on the cables.

- Avoid overcrowding the tray and ensure that cables are routed in a way that minimizes the risk of damage.

- Environmental Factors:

- Monitor the environmental conditions around the cable tray and address any issues that could affect its performance or longevity.

- Consider factors such as temperature extremes, humidity, and exposure to corrosive substances.

Comparison with Other Cable Tray Types

Wire mesh cable trays offer distinct advantages compared to other cable tray types:

- Ladder Racks: Ladder racks provide more structural support and are suitable for heavier cable loads. However, they may have limited ventilation and can be more difficult to install.

- Perforated Trays: Perforated trays offer a balance between ventilation and support, but they may not be as flexible or adaptable as wire mesh trays.

- Solid-Bottom Trays: Solid-bottom trays provide maximum protection for cables but have limited ventilation and can be more difficult to inspect or modify.

FAQs

- What is the difference between wire mesh cable trays and ladder racks?

- Wire mesh cable trays offer better ventilation and flexibility, while ladder racks provide more structural support for heavier loads.

- Can wire mesh cable trays be used outdoors?

- Yes, wire mesh cable trays made from galvanized steel or stainless steel are suitable for outdoor applications.

- How do I choose the right size of wire mesh cable tray?

- Consider the cable diameter, number of cables, and load capacity when selecting the appropriate size.

- Can wire mesh cable trays be used in corrosive environments?

- Yes, wire mesh cable trays made from stainless steel are highly resistant to corrosion and are suitable for such environments.

- How often should wire mesh cable trays be inspected and maintained?

- Regular inspections and maintenance are recommended, typically at least once a year or more frequently depending on the specific application and environmental conditions.

Conclusion

Wire mesh cable trays offer a versatile and effective solution for managing electrical cables in a wide range of applications. Their open design, durability, and ease of installation make them a popular choice among engineers, contractors, and facility managers. By carefully considering the factors discussed in this guide, you can select the optimal wire mesh cable tray to meet your specific needs and ensure a safe, reliable, and efficient electrical infrastructure.

This article was created with the help of Gemini

Pingback: Máng Cáp Lưới Là Gì? Ưu Và Nhược Điểm - Thesun.vn